Pucel Enterprises was founded in 1949 by Edward L. Pucel and has quickly become one of the industry leaders in industrial storage solutions and metal storage systems. All products are manufactured in the U.S.A. and feature heavy duty all welded construction. We have been family owned and operated for over 70 years.

We Work With You

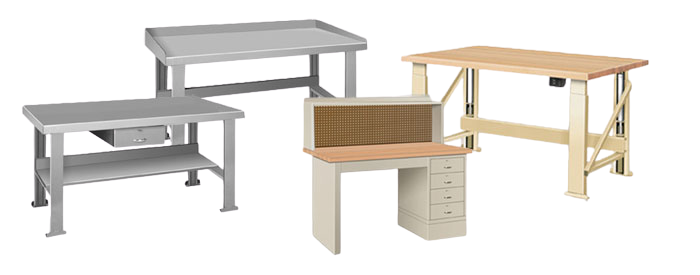

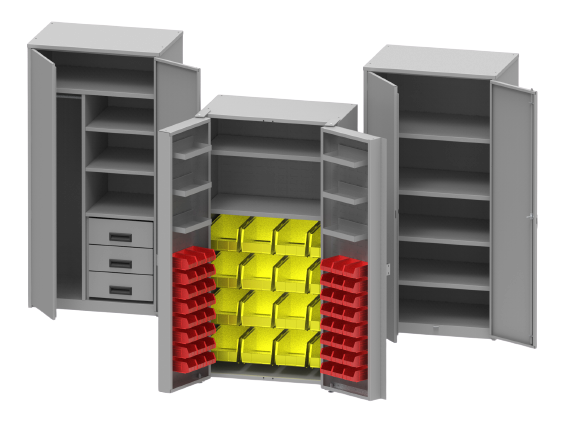

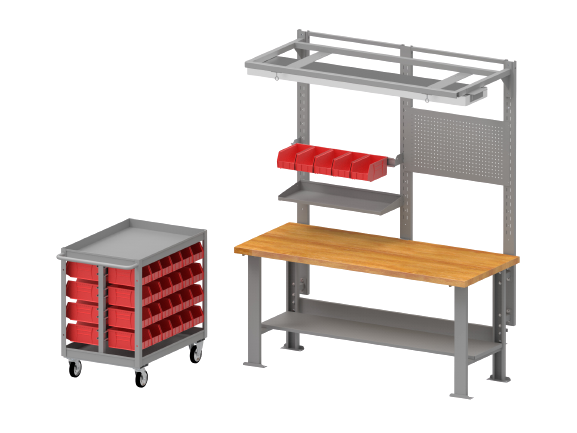

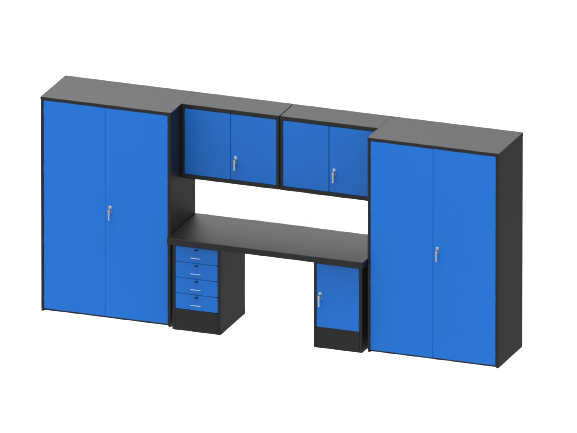

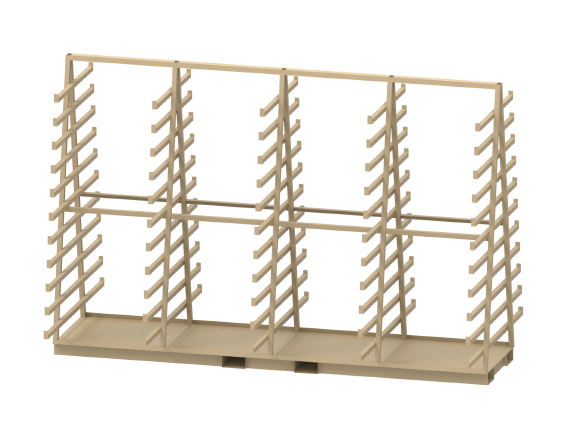

As a material handling equipment manufacturer, our Research and Development department constantly strives to respond to the needs of our customers. In addition to our standard product line we can modify or customize any product to fit your specifications. We will work with you through the process of designing, engineering, developing, and manufacturing of your product. Click the button below to get started on your custom order!

Looking to Purchase Our Products

As an industrial equipment manufacturer, Pucel's products are available nationwide through a network of Industrial Distributors. Click the button to the right and submit the form to receive the name of your nearest distributor. If you would like to become a distributor of Pucel's products, please complete the Become a Distributor form and we will be in touch very soon. We look forward to working with you.

Industries Served

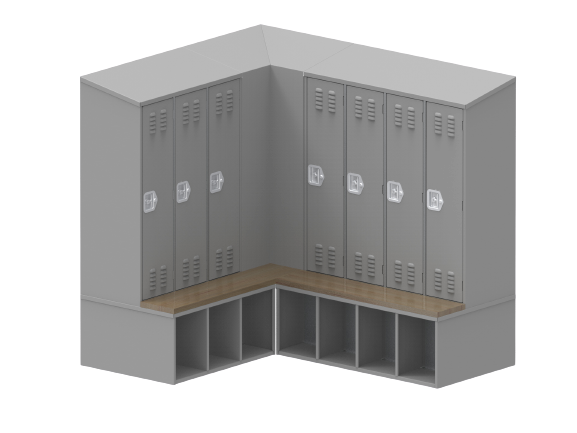

Pucel's products can be found in a variety of industries around the world including - manufacturing, medical, education & training facilities, military, and automotive. Pucel strives to provide products that can be customized no matter what industry, job, or department you are in. Whether you are in need of an inventory control cabinet in the medical industry or in need of a workstation on the assembly line of the automotive industry, Pucel has products to fit your needs. Click below to find out more information.

PUCEL ENTERPRISES, INC.

1440 E 36th Street, Cleveland, OH 44114

P: 800.336.4986

.png)